Professional equipment

KIRA CV 60/1 Autonomous & Stand-On vacuum

Role: Director of Industrial Design

Stand-on equipment was developed for efficiency. Karcher’s solutions had become dated, and times were rapidly changing. Cleaning efficiency demands were increasing, and autonomous technologies were finally ready for the application. Ethnography and field research led to valuable discoveries which we embodied into a new machine platform, designed from the ground up to accommodate robotic or manual cleaning - a first for the industry. Additionally, my team broke new ground in UX, developing ground breaking robotic socialization and communication standards.

iCapsol - Interim Carpet Cleaner

Role: Industrial Design Consultant, Team Lead

Deep carpet cleaning is time consuming and leaves carpet wet but vacuums don’t remove more than dry soils near the surface. There was an opportunity to create a new category. Focusing on high maneuverability and durability, a new concept was born. Counter rotating brushes gave our new machine a weightless floating feeling while enabling cleaning in any direction. The rubber overmolded handle, and cast aluminum console provided a comfortable and intuitive user experience. It received the Innovation Award from the International Sanitary Services Association (ISSA).

Disinfecting mister

Role: Director of Industrial Design

This product originated from a desperate need in healthcare to reduce HAI’s - healthcare acquired infections. While successful, it was also very expensive to produce as it was 100% fabricated. The time to invest in a tooled redesign had come. The fast 6 month development brought reduced cost and labor. Users appreciated the easy to clean tank, integrated cord storage, and easy charging. The elegant and durable design fits cohesively into Karcher’s portfolio and contributed $4M in net profits in its first month of production.

Large Steerable Extractor

Role: Director of Industrial Design

Karcher had developed a 360* steering concept that would much improve user experience operating large extractors. My team had begun developing the next generation of user interface, and this large extractor redesign was the perfect opportunity to bring it all together. The industrial design results include a tilted back “service position” for easy access to the brush deck as well as a UI that became the global standard and is developed into all new equipment.

High Efficiency Hot Water Portable Pressure Washer

Role: Director of Industrial Design

This tightrope of a project required redesigning a very inefficient machine that had a strong cult-like following and strong sales, and heavy brand association to the large burner. Think gas guzzling muscle car. Pending efficiency regulations were a threat to this machine, and R&D had recently finished developing a highly efficient burner that also happened to be much smaller. By combining the forms of the much smaller burner with a new control tower, the team achieved a hotrod-like appearance that relieved the dealers. Customers were delighted with the benefits and ease of use improvements.

High Efficiency Hot Water Portable Pressure Washer

Role: Director of Industrial Design

Karcher had been unable to gain US traction with European market machine designs. Customer needs in the US are different, and a global development team was tasked with designing a rugged, simple, and serviceable machine to strengthen Karcher in professional markets. The team achieved a burly form by focusing on rotationally molded tanks and a steel tubing protective cage. The improved durability and usability were so successful that Landa dealers demanded access to sell the machine and now proudly sell the Karcher brand.

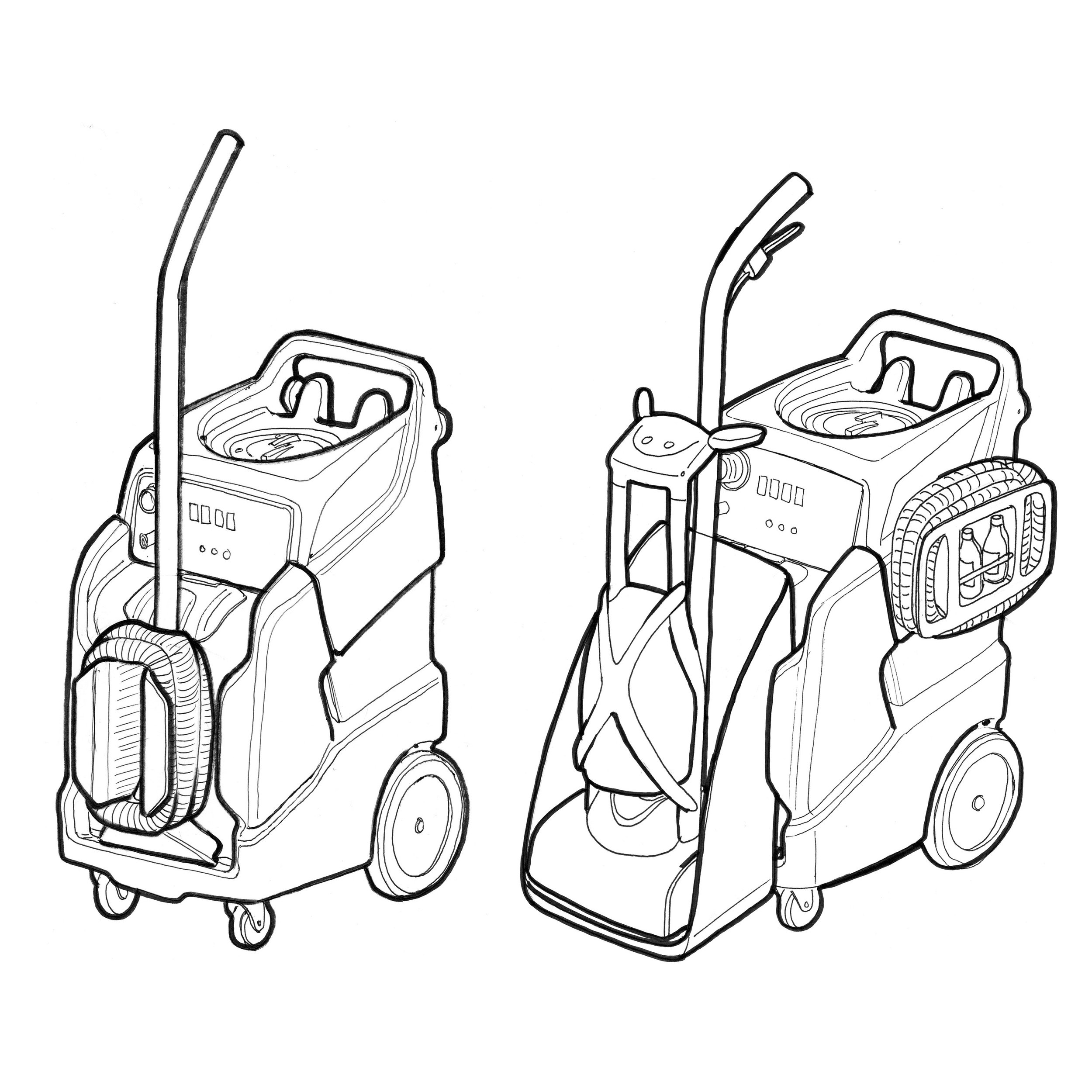

Portable Large Extractor & ergonomic wand

Role: Industrial Design Consultant, Team Lead

Windsor Industries asked me to ground-up design a large portable carpet extractor as a new addition to their portfolio. These “box and wand” machines are known for being difficult to transport and all the different tools require many trips to the contractor’s truck, adding lots of time to a job. The new professional design considered storage for all tools needed and simplified the task of loading into trucks. Additionally, I developed the Aquafoil wand to lauch with this extractor. It’s ergonomic shape, airflow optimized head, and light weight aluminum construction disrupted the industry and established a new revenue stream for Windsor.

Nu Wave Wide Area Vacuum

Role: Industrial Design Consultant, Team Lead

Windsor Industries contracted me to a design a replacement for the outdated private label vacuum they had been selling. My development focused on high level needs such as ergonomics, filter bag change, cord storage, and user interface. Customers were delighted to have a comfortable adjustable handle with quick access to controls. The 3 point cord wrap was fast to use and quick release. Vacuum bag access was a human factors win.

High Flow Portable Pressure Washer

Role: Director of Industrial Design

My team was tasked to develop a new pressure washer addressing the very high flow, portability, and safety needs of agricultural and marine markets. Tube forming expertise was leveraged to create a protective cage and accessory fastening opportunities. A heavy duty base was designed for easy conversion from wheeled cart to skid mount on a trailer - a very important aspect for meeting the needs of the main 2 and very different user types.

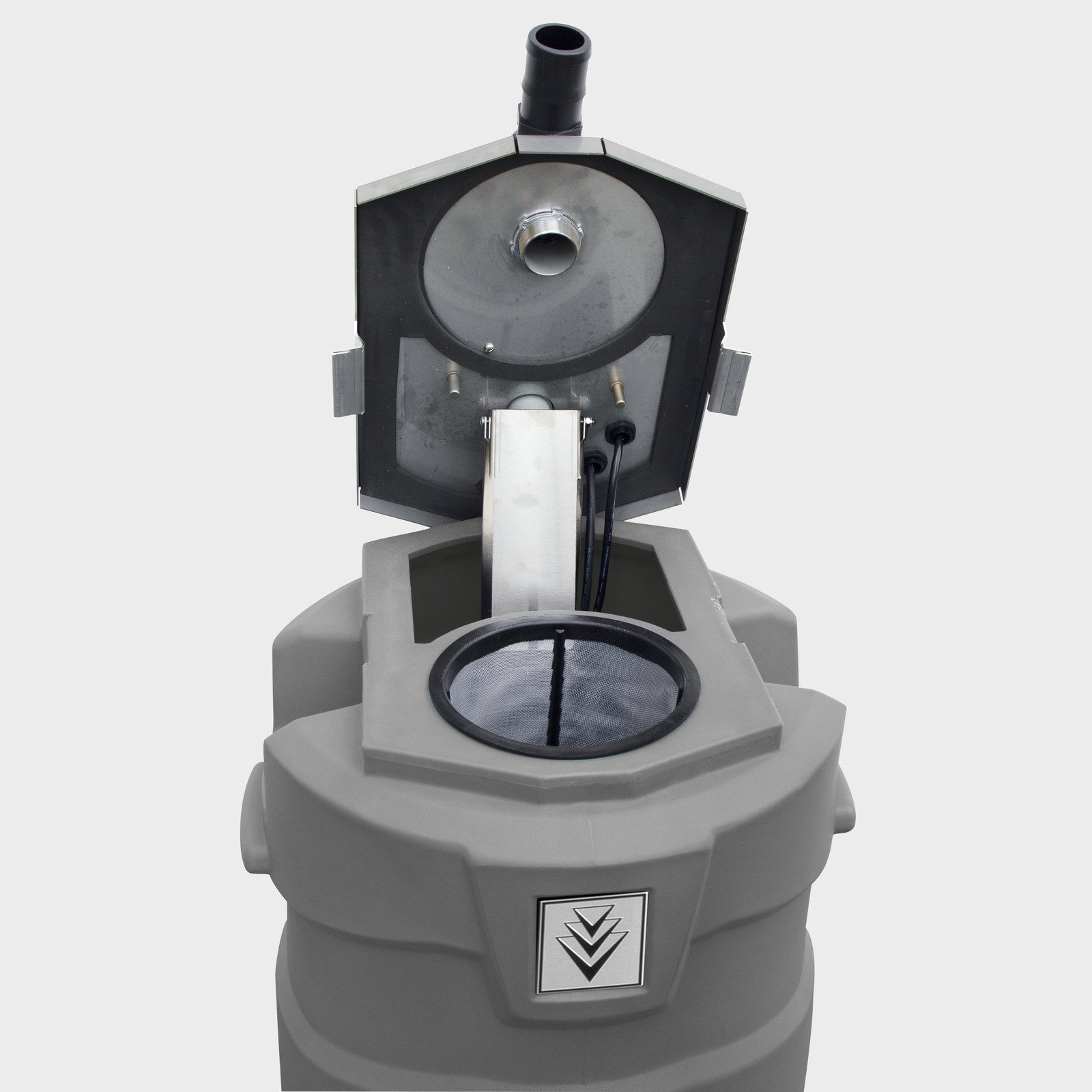

Waste Water Reclaim

Role: Director of Industrial Design

EPA regulations are driving requirements for contract cleaners to reclaim wastewater. It was our duty to empower our customers by developing a solution for wastewater containment, recovery, and disposal. The extremely easy to use system could be wheeled to location or mounted to a contractor’s trailer. The “Mississippi” was embraced by dealers and customers, all while promoting best practices for a cleaner environment.

WASTE WATER RECLAIM & RECYCLE

Role: Director of Industrial Design

As water scarcity becomes the norm, driving regulations and pushing costs higher, Karcher’s development team set off to empower professional customers with water recycling. Exploration of rotationally molded tanks reinforced with steel frames proved a robust framework. Design constraints focused on contract cleaning trailer systems while no compromises were made around simple usage and maintenance. The very well thought through system is destined to please customers and help the planet.

carpet cleaner UX Projects

Role: Director of Industrial Design

Handle for Large carpet cleaner

Carpet extraction is hard work. The machines are heavy and must be muscled around. Additionally, the machines are used both forwards and backwards

Designed a rubber over-molded handle handle to accommodate the many user position possibilities. Integrated momentary switch buttons in three areas to ensure easy machine activation

Handle for Rental carpet cleaner

A newly designed rental carpet extractor was in need of an ergonomic and simple handle design and user interface

Designed an injection molded handle over a steel tube armature. The integrated button was natural for users to activate, and the clamshell style enabled easy replacement - an important rental market need. The clear dome provided instant feedback the machine was working and the rubber tank handle enabled balanced and easy water disposal

Drive Motor Switch and Handle Design for XL carpet cleaner

The self-propelled Commodore large walk behind extractor needed a drive motor switch solution integrated into handles

Created an intuitive method to engage the drive motor with a focus on a safe and ergonomic operating experience

Designed and integrated unencumbering & ergonomic momentary switches into the handles with a focus on safety and intuitive use. The Feather-touch buttons engaged the drive motor and accommodated a variety of natural hand positions, minimizing fatigue